Prepare for that great crop - storage and cleaning

Are the combine(s) fast enough? Are there enough trucks ready to move the grain to a bin or bagging area? Maybe the ground is wet, so is a grain cart ready to move the grain off the field towards a truck, bin, or bagging area? Is the bagger ready with enough bags? Are the transfers, augers or conveyors able to quickly unload the grain and move it, which allows for the combine to keep moving without having to wait for unloading?

And once it's off, if you didn’t catch the fusarium with spraying, well it’s not too late. You can use (1) a gravity table to separate the lighter infected kernels – the current best option for farmers, (2) a colour sorter/separator to pull then visually infected kernels – maybe not as good as a gravity table, or (3) a BoMill which is best used by end-users such as food processing facilities.”

Flaman Grain Cleaning and handling has all you need to get the crop into the bank.

Posted by Eric Anderson on Jun 28, 2016 in Crop reports

Tagged Crop Report, Auger, Conveyor, Grain, Handling,

Protect that great crop from fusarium

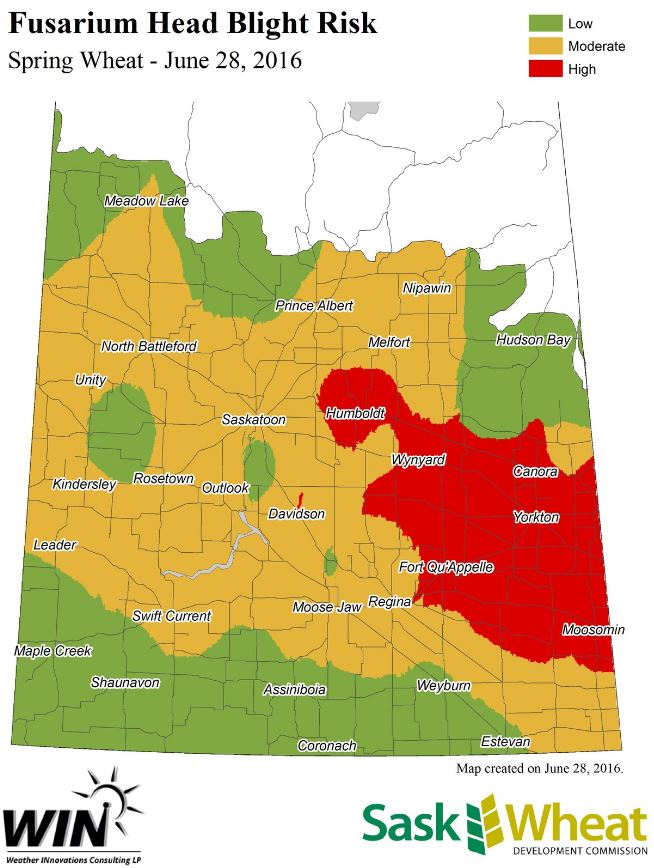

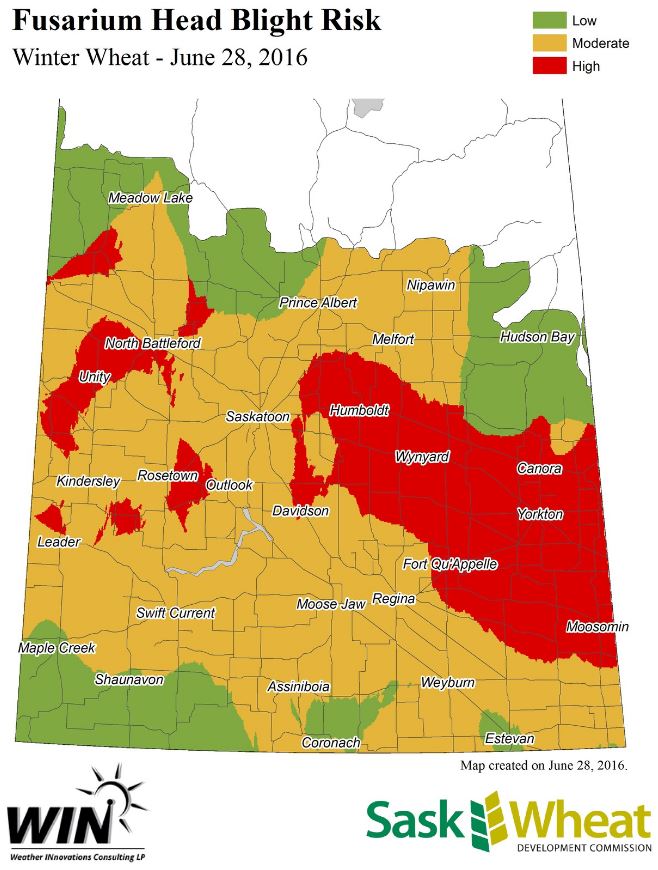

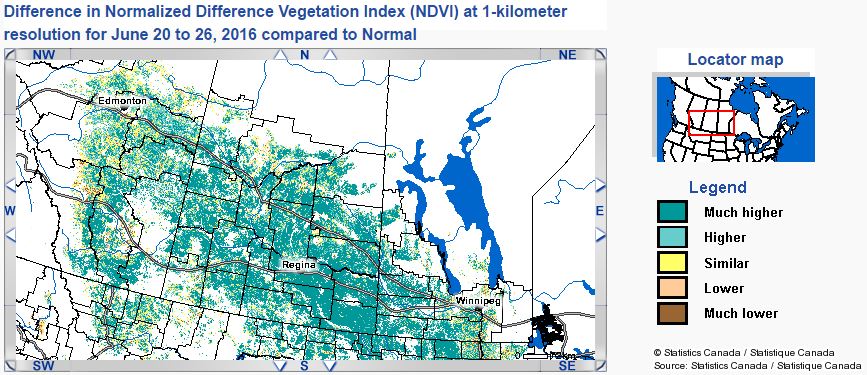

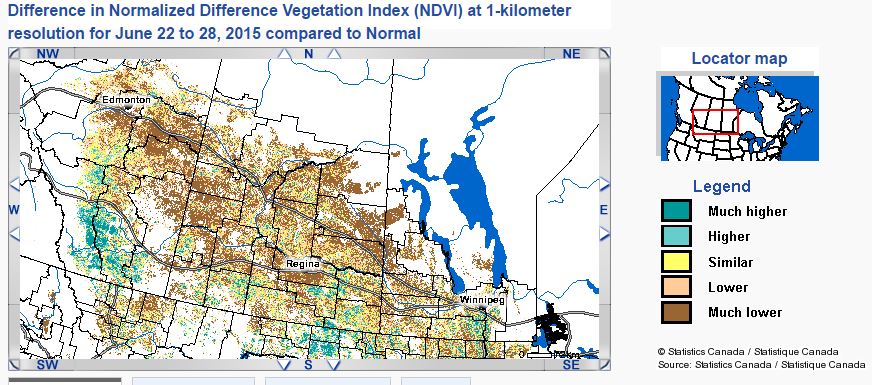

With the recent warm and wet weather, the fusarium risk is growing in Saskatchewan and ongoing in Manitoba. Today's risk maps reveal the situation:

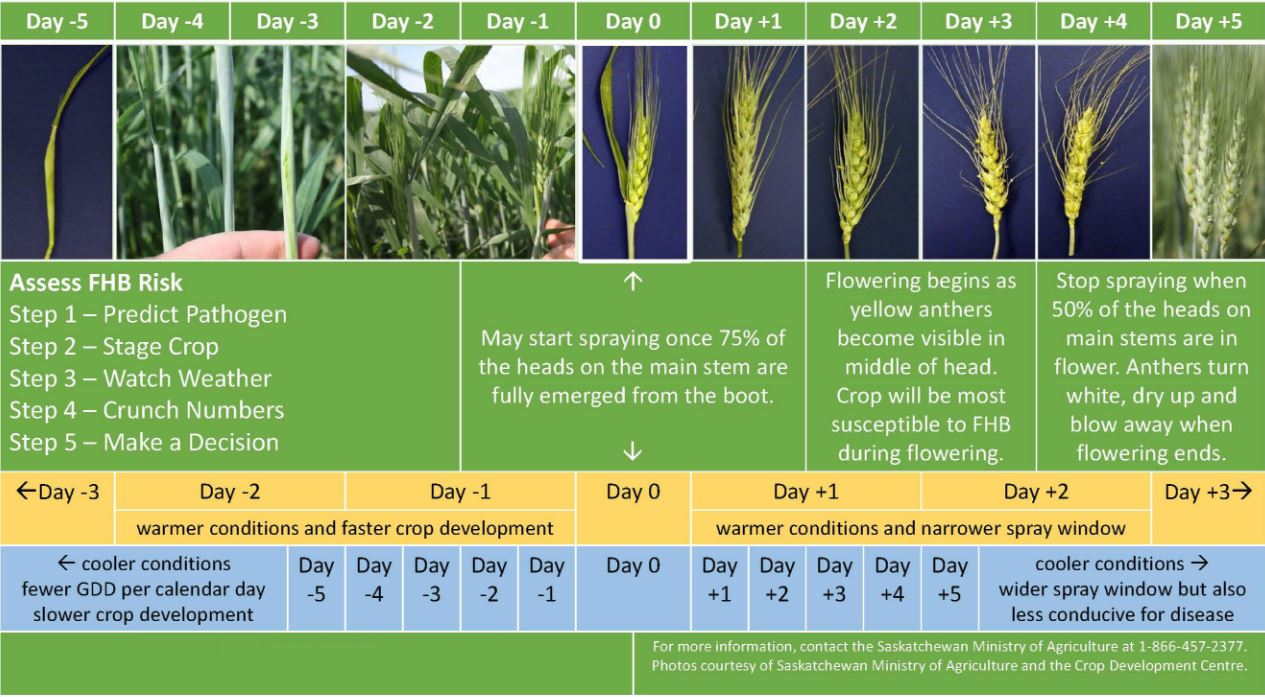

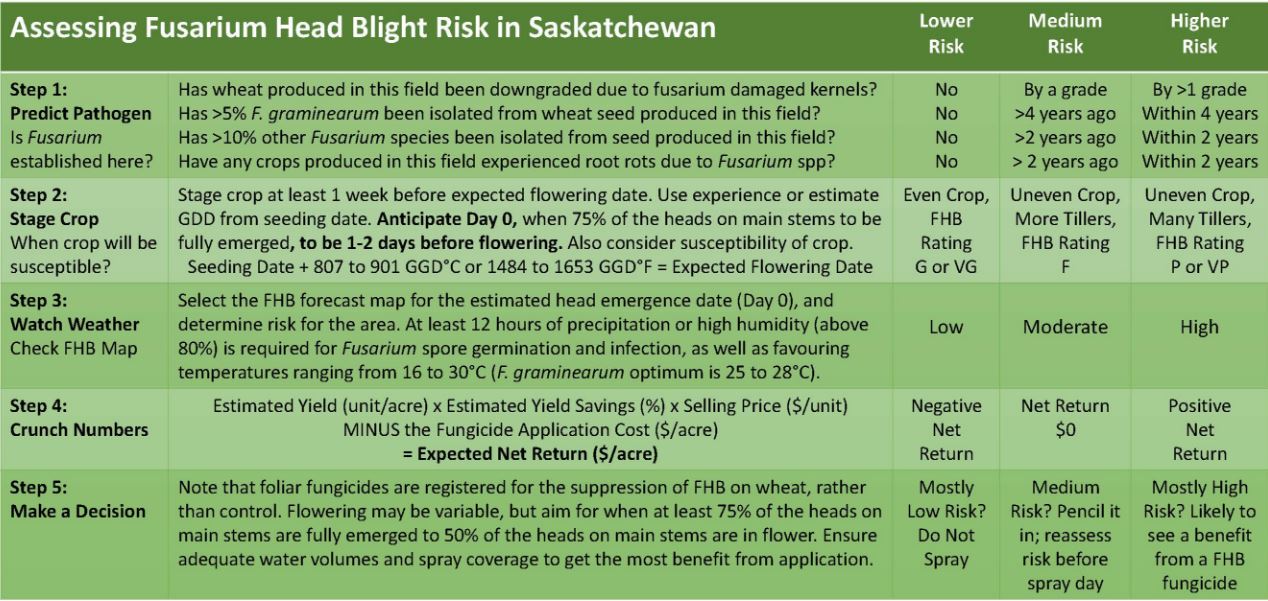

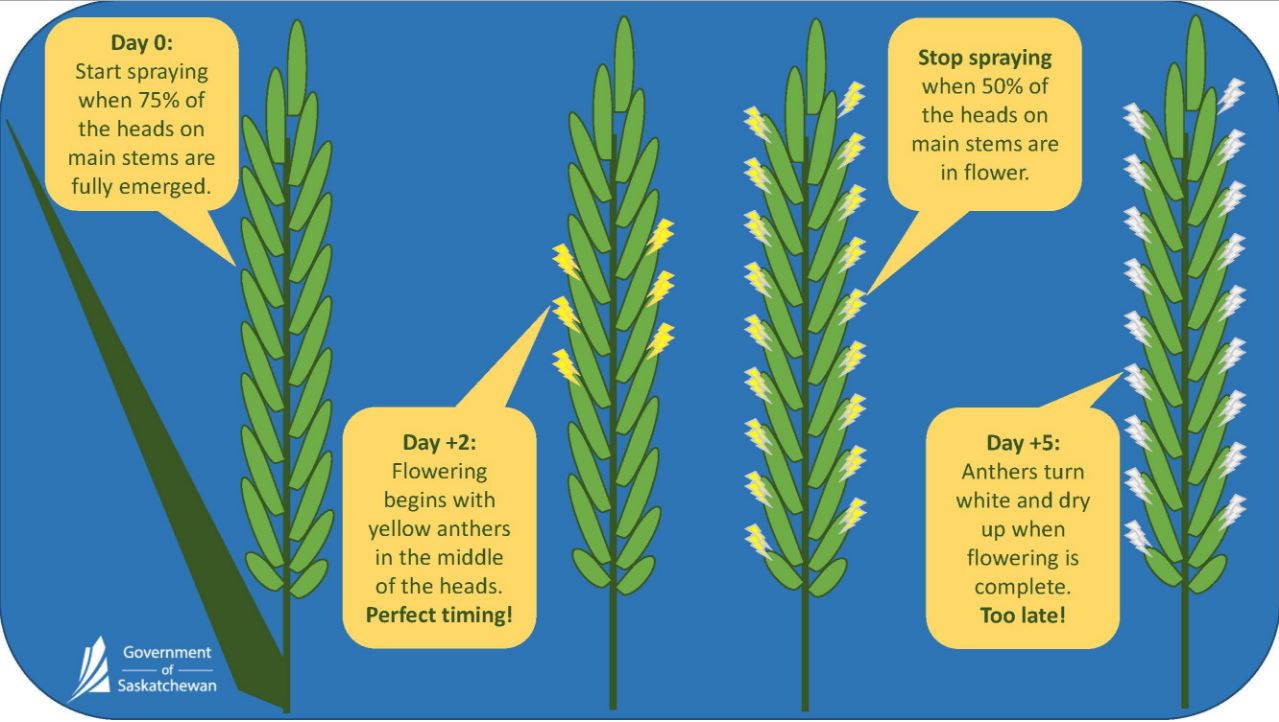

So, here are some handy charts to help you assess the risk and plan your spray:

This spraying requires the safe and accurate handling of chemical, and Flaman has what you need to do this.

Posted by Eric Anderson on Jun 28, 2016 in

Tagged Fusarium, Crop Assessment, Crop Report

Great crops forecasted - at least twice

This year:

Last year:

Posted by Eric Anderson on Jun 28, 2016 in Crop reports

Tagged Crop Assessment, Crop Condition, Protect, Fusarium

Is everybody ready for a potentially record setting crop?

APAS said it's anyone’s guess whether it will reach the record-setting levels farmers experienced in 2013 (38.4 million tonnes, according to Statistics Canada), but either way, APAS president Norm Hall wants rail companies to be ready. “If you remember three years ago when we had the potential of a huge crop, and turned out to be the largest crop on record, the railroads used the excuse that oh, we didn’t know this was coming, we weren’t prepared for it,” explained Hall in an interview with News Talk Radio.

So, APAS is asking the railroads to be ready to handle the grain - but they are the end of the system - the system begins with farmers?

Are farmers ready to harvest the crop within the small window of opportunity presented by crop development and the weather.

Are the combine(s) fast enough? Are there enough trucks ready to move the grain to a bin or bagging area? Maybe the ground is wet, so is a grain cart ready to move the grain off the field towards a truck, bin, or bagging area? Is the bagger ready with enough bags? Are the transfers, augers or conveyors able to quickly unload the grain and move it, which allows for the combine to keep moving without having to wait for unloading?

And after moving the grain by rail, are the ports and ships ready?

APAS has put rail on notice, but what about the rest of the system?

Posted by Eric Anderson on Jun 23, 2016 in Crop reports

BoMill TriQ: A Fusarium Management Solution

The newest technology being brought to the Canadian agriculture industry has benefits for everyone. BoMill, a Swedish company, offers a management solution to the fusarium problem that’s been a growing concern in Western Canada. The BoMill TriQ is a grain sorter that sorts wheat, durum, and barley by protein, vitreousness, and fusarium. Sheldon Ball, the sorter specialist at Flaman, says, “It’s the only product we’re aware of that sorts individual kernels by fusarium.” BoMill increases the accuracy of other processes by analyzing the chemical make-up of kernels, not just the colour, and it does it by individual kernel, instead of in a batch.

WHY BOTHER?

FUSARIUM

Fusarium is a fungus that produces mycotoxins during the infection process. Mycotoxins are toxic and are not destroyed during processing such as milling, baking, malting, or ethanol production.* The BoMill TriQ grain quality sorter will sort the yields and improve the quality for a top selling dollar. More importantly, the sorted yield will be a safer product for final consumption.

VITREOUSNESS

The TriQ is also an excellent tool to clean grain for seed. Its patented technology (read about the NIT below) analyzes the ability a kernel has for germination, or its vitreousness. By setting a fraction to sort by vitreousness, you can get a yield that is 100% capable of germination. Talk about bumper crop potential!

HOW IT’S DONE – FEATURES OF THE BOMILL TRIQ

NIT Technology

NIT (Near Infrared Transmission) Technology is a patented sensory system that utilizes infrared light to test the chemical make up of a kernel. This new technology, found only in the BoMill IQ and TriQ products, allows kernels to be sorted according to their germination capabilities (vitreousness), fusarium, and protein content. This technology is capable of yielded a 100% vitreous output, which translates to guaranteed better yield if used for seed. It also means healthier product for consumption by people and animals.

Individual Kernel Analysis

Although other machines exist that focus on individual kernel sorting, such as color sorting, this is the first machine that sorts individual kernels by fusarium. Other methods will take a batch of grain and sort by weight, making heavier and lighter kernels separate to the top and bottom. This is a good method, however the individual kernel analysis yields a higher accuracy.

Wireless Monitoring

The graphical user interface makes it possible to control the sorting using any device with a browser, such as a PC, tablet, or smartphone. Due to its user-friendly design, it makes the training sessions intuitive and time efficient.

WHERE CAN YOU LEARN MORE?

Flaman Grain Cleaning is the licensed dealer in Canada for BoMill’s grain sorters. “With Flaman as our Distributor in Canada we will have a strong partner,” says Karin Wehlin, CEO BoMill AB. “Flaman’s long presence in the grain cleaning market and know-how as well as established service organization is important for our future”. You can contact one of Flaman’s staff members to get more information by email or by calling 1-888-435-2626. You can also visit the product page for the BoMill TriQ and IQ products.

*Website: https://www.agriculture.gov.sk.ca/fusarium-head-blight

...

Posted by April Basset on Mar 25, 2015 in New Products

Tagged Grain Cleaning, Fusarium, Grain Sorting, Bomill, TriQ, Wheat Cleaning, Durum, Barley, Optical Sorting,

Flaman is a Top 100 Small/Medium Employer!

Read the official press release https://www.canadastop100.com/temp/sme2015.pdf ...

Posted by Flaman on Mar 19, 2015 in Local News

Tagged Top 100, Eluta.ca, SME, Proud, Flaman Sales, Flaman Group Of Companies

Harvest Time - Around the Corner

Mitch Flaman ...

Posted by Mitch Flaman on Aug 21, 2014 in Division News

Tagged Harvest, Last Season, Weather

Flaman named Top 100 Company

Flaman Group of Companies is proud to announce that we have been named #49 on Saskatchewan’s Top 100 Companies List for 2013. ...

Posted by Jennifer Thompson on Sep 27, 2013 in Division News

Tagged Flaman, Top 100 Companies, Customer Service, Awards

Harvest Report: Crop progress and removing dockage

A few weeks ago when I started this blog entry, I was excited to report that agriculture equipment dealerships were approaching sold-out inventory levels and already delivering machinery to numerous producers province-wide. It was actually a bittersweet situation getting stuck on a secondary highway behind a semi hauling a combine for 16 miles with no option to pass. But, on the other hand, it was exciting to know that harvest was just around the corner. Needless to say, a few weeks later harvest is now in full swing and farmers are going hard....

Posted by Mitch Flaman on Sep 6, 2013 in Product Information

Tagged Grain Cleaning, Harvest, Kwik Kleen Uses, Removing Kochia

On the Road with Flaman Grain Cleaning

Although we thought it would never come, it’s beginning to look a lot like summer on the prairies. The snow is finally gone and the drills seem to be making the last few laps as seeding is wrapping up in many areas. ...

Posted by Mitch Flaman on May 27, 2013 in Division News

Tagged Grain Cleaning, Seeding, Flaman, Summer, Farm Progress Show